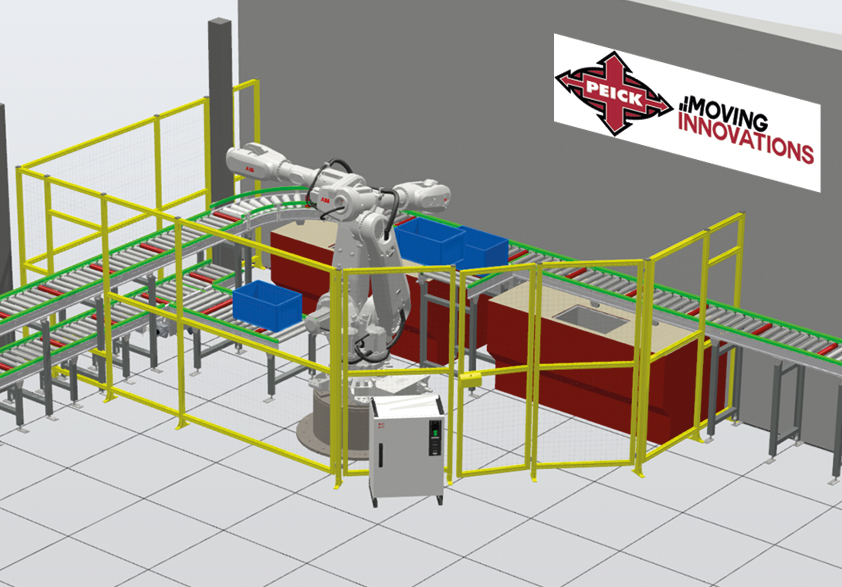

Bin in Bin Picking

Focus

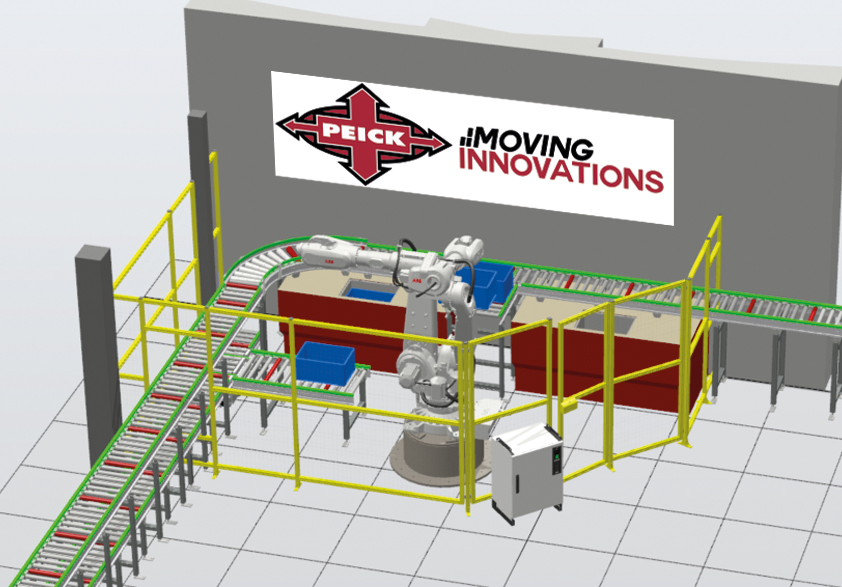

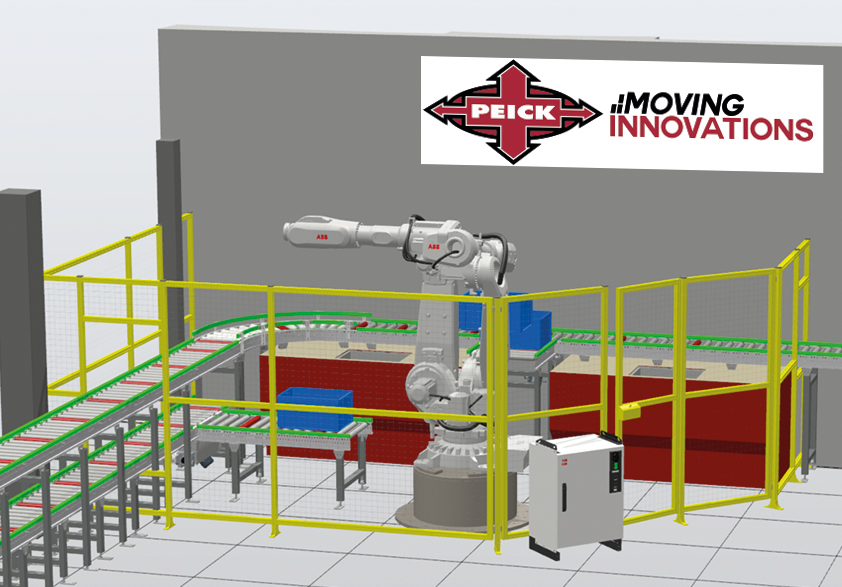

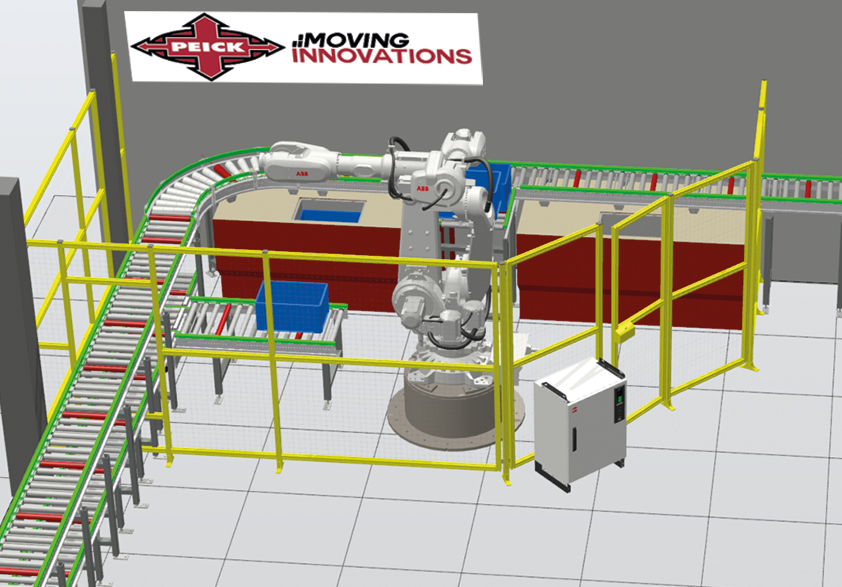

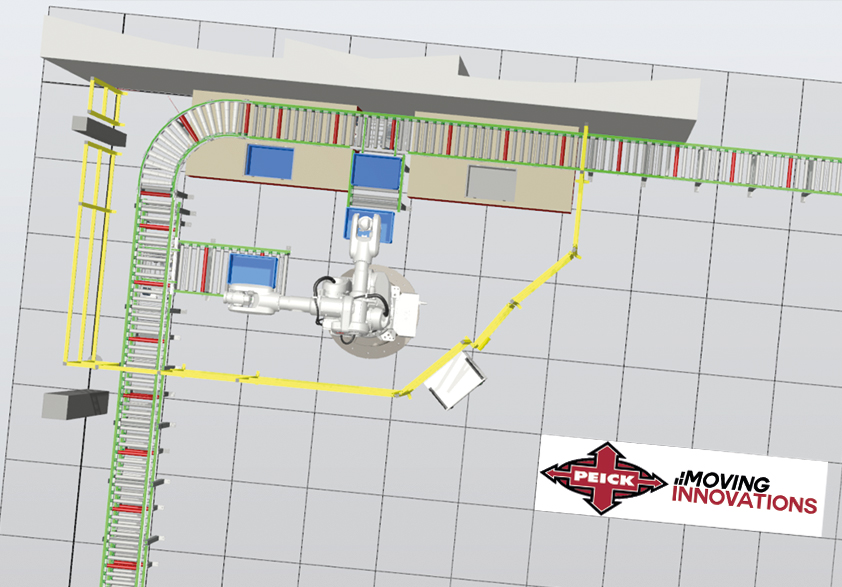

Automated insertion

of KLTs in Matrix XY

Automated removal

of KLTs in the Martix XY

Efficiency and flexibility

This case study focuses on automating the insertion and removal of KLTs in the Matrix XY. This process plays a crucial role in modern warehouse and logistics systems.

Our robotic solution enables a smooth infeed and outfeed of the KLTs with the help of Peick conveyor technology. This solution achieves an impressive throughput of up to 250 cases per hour and covers the reach of 2 carousel ports.

Our robots offer the flexibility to serve multiple ports simultaneously, which has a positive impact on the efficiency of Matriy XY systems. This case study provides insights into the possibilities of warehouse automation and how it can meet the requirements of modern warehouse management.

Learn more about this innovative solution and its potential for your warehouse logistics.