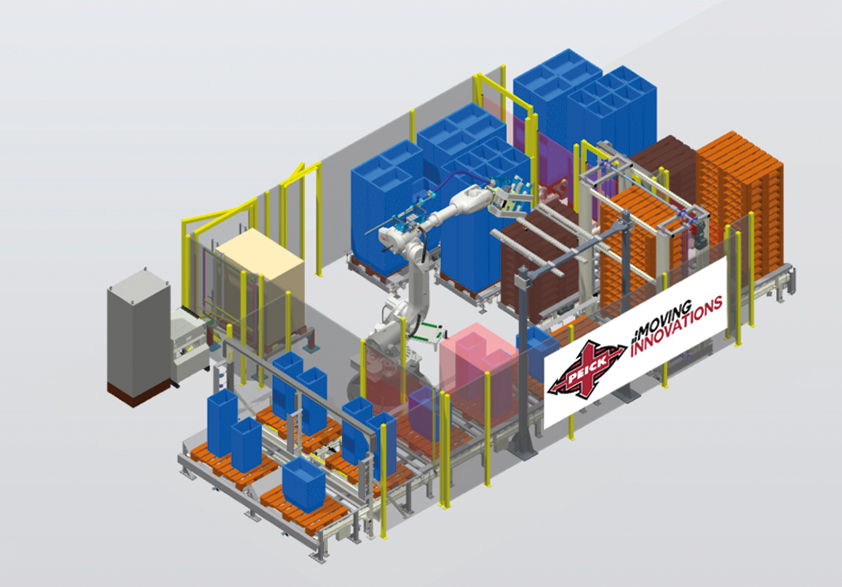

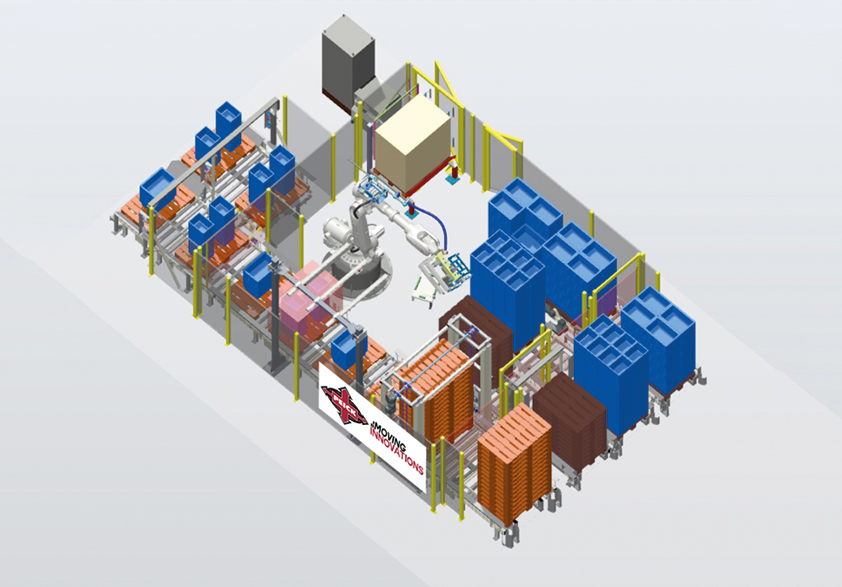

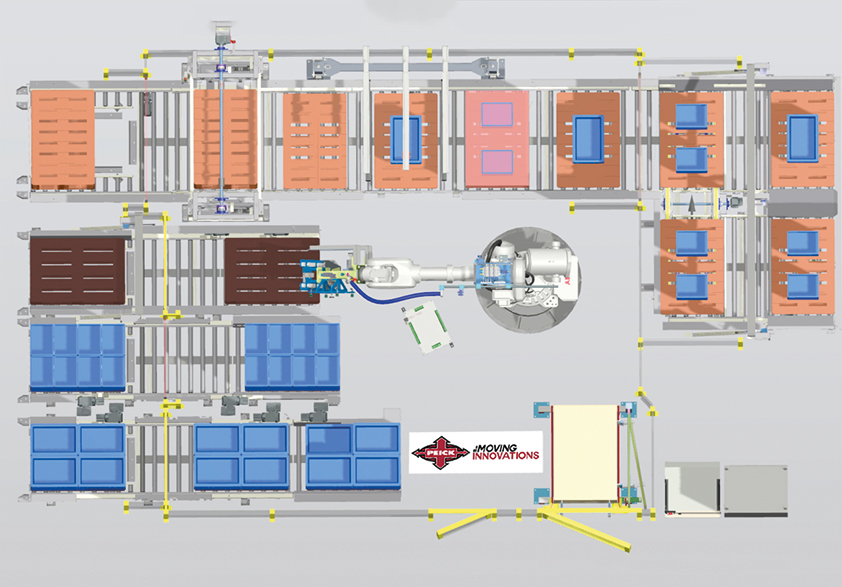

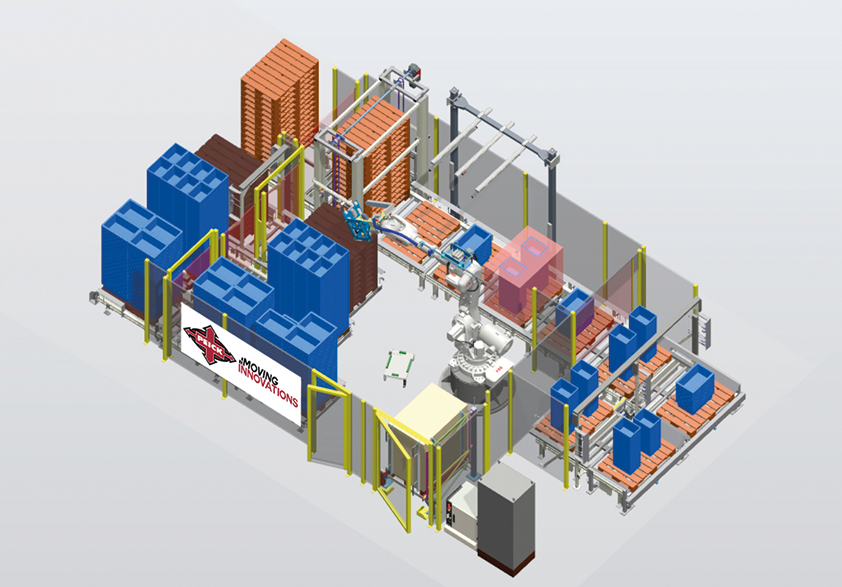

Palletizing of empty KLTs after storage process in an ET warehouse

Focus

Palletizing

of empty SLC after the storage process

Precise palletizing

by robots

Efficient palletizing of empty SLC

In this case study, we focus on the efficient palletizing of empty SLCs after the putaway process in an ET warehouse. These are various empty SLCs that are conveyed on pallets and our robot takes over the task of palletizing them precisely.

The process begins with empty SLCs of various types, whether stacked or as rotating stack containers, being conveyed on pallets to the robot. Our advanced camera technology detects the crate type as well as their exact position on the pallet. This enables our robot to safely grab the SLCs or stacks of crates and palletize them on another pallet.

Another advantage of our system is its speed. With an impressive throughput of up to 1250 SLCs per hour, we ensure that this process is handled quickly and efficiently. In addition, the extremely compact arrangement of conveyor technology and robotics ensures space savings in your warehouse.

After the pallet is fully palletized, our robot puts on a cardboard lid to ensure the safety of the load and further optimize the shipping process.

Learn more about our solution and how it can optimize palletizing of empty SLCs in your warehouse.